No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

After our development of our product we manufacture & assemble your prototype.

We also take over the series production of your product.

Visit us on Google Maps for a virtual tour of Optomech GmbH.

In order to guarantee you a high quality, we are ISO 9001 certified.

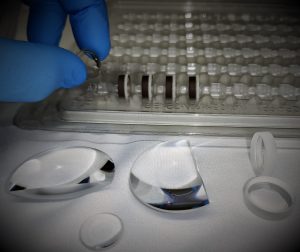

We assemble your components in our 160 square metre ISO 9 class clean room – both prototypes and series! (Google Maps Tour)

Assembly takes place under laminar flow boxes. There we achieve a level of cleanliness that corresponds to cleanroom class ISO 5. We currently have five workstations with laminar flow boxes at our disposal. However, we can expand to up to 10 such workstations if required.

160 qm cleanroom with 5 Laminar Flow Boxes

left: Laminar Flow Box

right: ESD-safe soldering workstation

Optomech has its own in-house workshop with turning and milling machines.[/caption]

Your benefits:

In addition, your components can be fitted with a “Corporate Design” surface coating adapted to the optical application.

If necessary, parts can be cleaned and packed in the cleanroom.

Examples of aluminium components, black anodized

Our CNC turning machine Haas CL-1

Our workshop has 2 compact Datron Neo high-speed milling machines

The high quality of our production can be checked with our keyence-IM-7010 measuring head. If necessary, we will provide you with a measurement protocol.

Optomech has a wide network of optics manufacturers. We are happy to support you in designing and selecting the right optics for your product. Optomech coordinates the production and compensation of your optical parts.

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.